curves

Rods & Mortar – curved glass block walls

Curved glass block walls can only be constructed using Rods & Mortar.

Planning the design of a curved wall uses the same principles of constructing a flat wall. Additional considerations to address are calculating the opening size, ensuring the internal radius is sufficient in respect of the block size being used and positioning of intermediate vertical slip joints.

Opening size

To set out the opening size dimensions for a curved glass block wall panel, the calculation is done in the same manner as a straight panel. However the calculation should be done from the inside face of the curve (shortest radii). The outer width of the curve will be wider because the vertical joint is opened to form a curve (longest radii).

Expansion joints and curved glass block walling

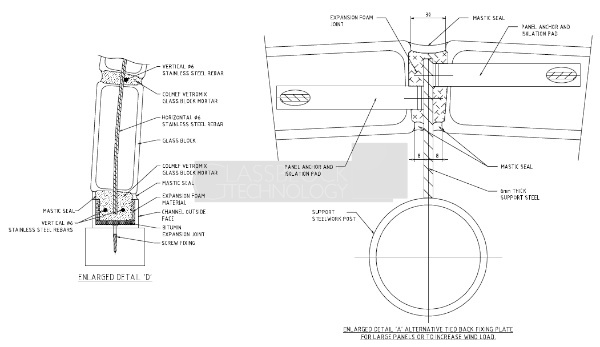

Curved walls are very stable, due to the shape. However, ensuring they are restrained sufficiently to the perimeter opening is important. Between the opening and glass blocks, should be an expansion joint (soft joint) incorporated to the head and jambs. A bitumen fibre or high-density neoprene should be inserted at the base.

The perimeter soft joint should be sealed by caulking with silicone and not grouted over with mortar as bridging the joint will restrict expansion and contraction and may lead to either the blocks or mortar joints cracking. Intermediate vertical expansion joints are also required whenever the curve changes plane. The joint only needs to be incorporated vertically and is designed to cope with lateral forces – the opposite flows of the curve expand towards each other, absorbing the compression.

A joint caulked with a Rods & Mortar white sealant will visually look similar to a standard mortar joint.

Joint sizes and minimum radii

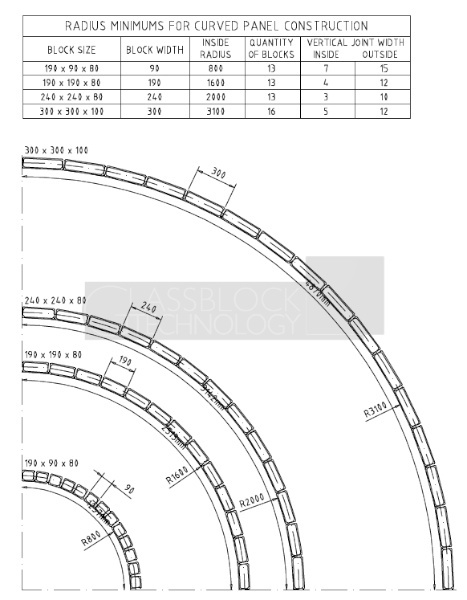

When designing or building a curve, the internal radius dimension is one of the first items to consider to ensure the external vertical joint is not too wide and looks aesthetically in proportion with the horizontal joints. Also it is crucial that it does not exceed 22mm, as it may be susceptible to cracking.

The radius is calculated in conjunction with the block dimension, so a smaller radius is possible with a 90x190mm block in comparison with a 190x190mm block.

A 6mm spacer used internally will achieve a narrower external vertical joint. This works well in conjunction with smaller format or half blocks, resulting in slimline vertical and horizontal internal and external joints.

Radius chart:

Curved openings and restraint

Glass block walls should be supported on a minimum of three sides, preferably four, to offer the greatest strength and support. The jambs or sides of an opening can be formed in various materials like brick or blockwork, concrete, steel or studwork. A safewall end post can be used as a secondary vertical jamb.

Reinforcement bars are supplied in 1200mm lengths as standard and are flexible enough to be formed to follow the flow of the curve.

If a curved wall is supported at the base, secured to one vertical edge and top edge, (the ceiling or a bulk-head) then the exposed edge can be finished using glass end blocks (double bars every horizontal course are recommended). If secured at the base and to one vertical edge with the top edge open (and not tied at the head) this is best constructed using end blocks and a double glass end block at the exposed corner. This will create an all glass effect.

rods & mortar curved glass block walls

rods & mortar curved glass block walls