installation

TOOLS REQUIRED

Drill, screwdriver, mitre saw or hacksaw, caulking gun, screws, pliers and spirit level.

ACCESSORIES REQUIRED

2.4m Easifix spacer profile, 185mm Easifix spacer profile stainless steel anchor brackets, Easifix adhesive, 71x15mm planed timber and Easifix sleeve.

PREPARATION OF OPENING

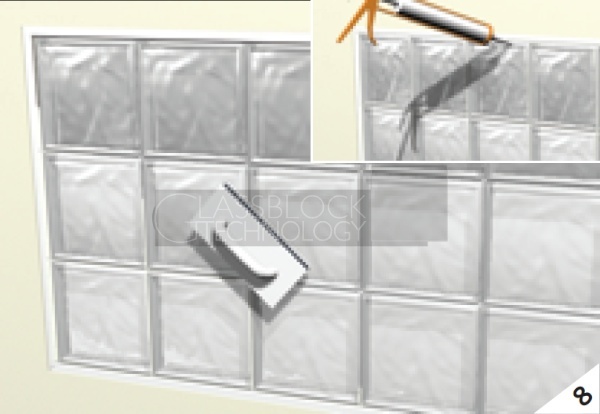

Cut 71 x 15mm planed timber and place into Easifix sleeve to create a neat finish. Mitre cut the corners of the Easifix sleeve.

Lay out blocks and Easifix spacers dry to ensure modules fit. Secure frame horizontally and vertically to surfaces at 600mm centres ensuring it is both square and perpendicular

LAYING FIRST COURSE

Cut long length of Easifix spacer fractionally shorter than the horizontal length of opening. Take two anchor brackets and bend prongs to a right angle using pliers. Insert prongs into holes of Easifix spacer at each end. The first horizontal Easifix can be screwed to the base/cill providing a firm base to begin constructing the panel. Note: The screw must be countersunk and not be in contact with any of the glass blocks. Silicone two 5mm beads of mastic into the under-side of the Easifix spacer fit to base of opening. Screw fix anchor brackets in place.

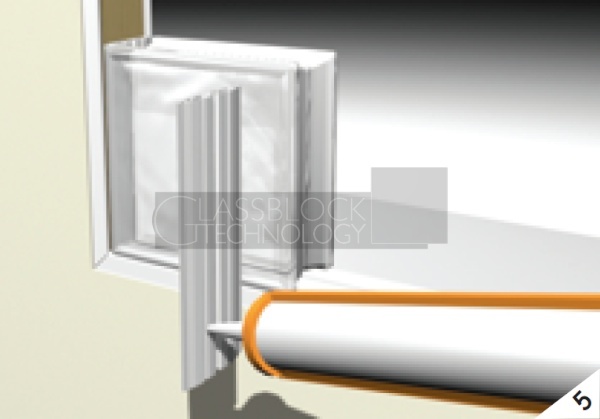

Take a 185mm length of spacer profile and silicone two beads of mastic on one side. Place over the anchor bracket. Silicone two beads of mastic to the easifix spacer profile. Fit first block. Take another piece of 185mm Easifix, apply silicone and fit to exposed vertical of first block. Fit next block and repeat this process until first row is complete. Note: Easifix spacer must always separate blocks from frame (fig.1). Remember each row has to be secured with anchor brackets.

FINISHING THE GLASS BLOCK PANEL

Repeat previous steps to complete the next and following rows.

SEALING AND WEATHERPROOFING THE GLASS BLOCK PANEL

When the wall is complete, caulk the joints with silicone. Alternatively, grout using a wide grout joint. The perimeter expansion joint should always be caulked with mastic to avoid bridging the expansion joint.

INITIAL CLEAN AND AFTER CARE MAINTENANCE

Do not clean with any acidic products, the best product for cleaning is water. Polish each block with a soft cloth using good old elbow grease. Note: Clean face of block as work proceeds. The glass block installer should have left the glass block wall in a clean, unblemished condition, requiring only periodical cleaning to maintain an excellent appearance. However, there may be a residue of cement on the glass surface left from mortar/tiling grout identified by whitish bloom when dry. This may be removed by use of proprietary cement stain remover.

HYDROFLUORIC ACID OR DERIVATIVES MUST NOT BE USED.

Paint or cement may be removed by a blade, taking care not to scratch the surface of the glass. Periodic cleaning is required using clean water and buffing up with a chamois leather or in clean water using a proprietary glass cleaner and cleaning off with a lint-free cloth.

easifix installation guide

easifix installation guide