specification

How a mortar joint works

Glass Block Technology mortar is a specially formulated premix bedding and finishing compound, available in one bag to be mixed with water. It is manufactured under factory controlled conditions so all additives are accurately blended and designed for maximum performance of strength, flexibility, water repellence and U-value.

Mixing instructions are on the reverse of each bag. Always ensure that water and bucket are clean and use a paddle drill. For optimum open time mix with cold water. Hot water may cause the mortar to set too quickly.

Traditionally sand and cement were used. If not consistently mixed , this can increase heat loss leaching and may not be necessarily water- or frost-proof.

A mortar joint will cure in reaction to air just like normal mortars, so it is important that the joint size is not below 6mm. This guarantees total curing and maximum strength. Vetromix will become solid within hours of construction. Total curing is achieved after 21-28 days.

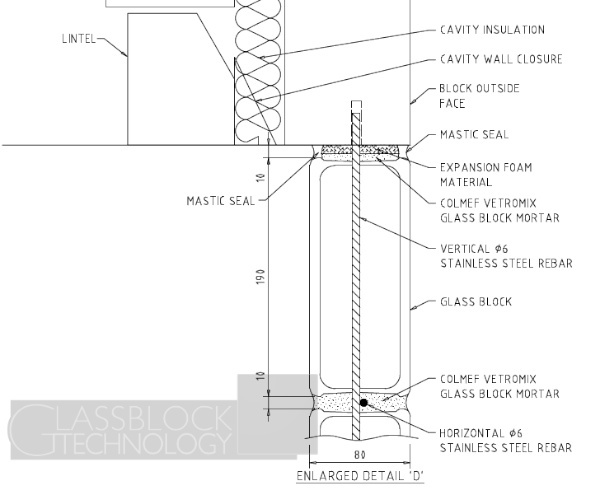

Glass is impervious unlike brick and concrete, therefore mortar is not absorbed into a glass block. The strength and support of a joint is created by the shape of the mortar profile (oval). The edge or collar of a block is concaved so when two are laid next to each other an oval joint is created.

This oval joint enables the glass block wall to resist impact or applied loads resulting in the panel being stable and self-supporting, but not load-bearing. Stainless steel reinforcement bars are used to restrain the panel to the surrounding aperture, whilst also giving the panel integral support and a wind-loading value.

The minimum recommended joint is 6mm and the most common used is 10mm. However, this is only the distance on show; the centre of the oval joint is always deeper from collar to collar. This area houses the stainless reinforcement bars, which should never be in direct contact with the glass surface.

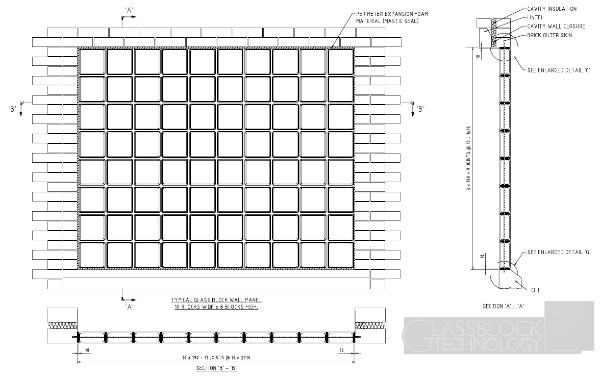

Calculating an opening size

When detailing a glass block wall, calculating the opening size correctly is the first and most important step as glass blocks cannot be cut. An opening can be calculated using a formula:

The dimension of the block plus the width of the joint multiplied by the number of glass blocks, plus one more joint width, equals minimum opening size.

If incorporating framing (such as U-channel or box section) the dimensions and tolerances need to be added to the formula measurement. If slip joints or support steel are required then this may also affect the opening size dimensions.

Framing is used for different reasons, whether aesthetic, performance-related or due to an incorrect opening size.

Framing may be considered in conjunction with other building finishes, such as cladding. It may serve a design purpose. If a building is rendered framing offers a solution as render can be applied up to the frame, creating a watertight seal whilst ensuring an expansion joint between frame and blocks is maintained (render must not bridge the expansion joint).

Frames may be required to divide or support glass block panels, vertically or horizontally. For example, if the panel is quite large it has to be supported at a high level or for a 360o curved rotunda. It is possible to design these frames or intermediate supports to be integral and hidden within the glass block construction or revealed to aesthetically enhance the feature.

When designing frames*, it is important to calculate the opening size required for the glass blocks (incorporating frame dimensions and tolerances). The opening is the number of glass blocks, plus the number of joints, including perimeter expansion. The following formula and example demonstrate this:

*Structural engineers need to advise on wind posts and shelf-angle calculations. These designs and specifications cannot be underwritten by Glass Block Technology Ltd as they are usually uniquely fabricated. U-channel and box sections are sometimes fabricated to specification but also standard sections are available off the shelf. It is advisable to seek assistance from steel specialists.